According to the World Bank report, unless current trends are reversed, the water crises will worsen. Around 80 countries are experiencing water shortages serious enough, to threaten agriculture, the report added.

It is generally accepted that irrigation is one of the cultural practices that stabilises yields and improves productivity in any agricultural development. Irrigation has long been associated with surface and overhead or sprinkler systems. Since the 1950s several high pressure and high volume sprinklers such as the Boom-o-Rain, Target Masters and Rain Guns have been introduced and are well adapted with the existing cropping system. However, with the rising cost of energy and an increasing competition for the available water, these high pressure systems are gradually being phased out and replaced by medium to low pressure systems such as the dragline and fairly recently by the mechanised and automated centre pivot system.

Selected for Show-case

INNOVATION 2008 BY Alumni IIT Mumabi

FEATURES

- INCREASE YIELD

- REDUCE WATER CONSUMPTION

- OPERATES ON SOLAR ENERGY

- IMPROVE MAN POWER

- IDEALLY SUITED FOR VARIOUS CROPS

Micro Pivot Irrigation Systems

- Optimal water conservation and productivity augmentation.

- Significantly helps lessen unabated impact of drought scourge on agriculture sector.

- The investment cost of the system is by far less to the drip system, which has been claimed to be one of the potential replacements for the overhead systems.

- The operating cost of a centre pivot system is as low as 25% as that of a comparable conventional sprinkler system

- It has also other features that make it attractive to irrigation managers. Trained personnel are not required to operate the machine.

- Water application can be easily adjusted to meet the soil and crop requirements. It also has greater management flexibility than other sprinkler systems. The system can be managed so as to apply the crop requirement either in small frequent doses or in one single application. Some models are computerised and therefore offer additional flexibility & versatility.

- Application of chemicals and fertilizers.

- Absorption of nitrogen gives more yield.

Our Pivot System :

Constant / Continuous move" approach introduced by us in the Pivot Business, has yielded extra crop, due to even distribution of water. This concept has resulted in synchronous tracking of all towers & thus resulted in uniform sprinkling, reducing wear & tare on the moving components as well as structural parts.

Solar Power is utilised as a prime power source to manage the entire movement of the pivot, making it total autonomous.

Some Facts for 4 Spans 25 Acre Machine :

1 Water pressure at the inlet 30 psi @ 150 gpm.

2 8 Hrs./day solar operation. Battery capacity can be increased as needed

3 "Constant / Continuous move" approach

4 All other advantages available with any standard pivot.

A) 30 to 50% water saving.

B) No erosion of land

C) 30 to 50%more yield

D) Application of chemicals and fertilizers.

E) Short payback period.

F) More nitrogen due to high Surface Area.

G) Minimal labor requirements

Sprinkler with Mist Formation :

Sprinkler with Mist Formation The only solor Powered Constant / Continuos Move Pivot Operational in the World, at Nasrapur, Maharashtra, India.

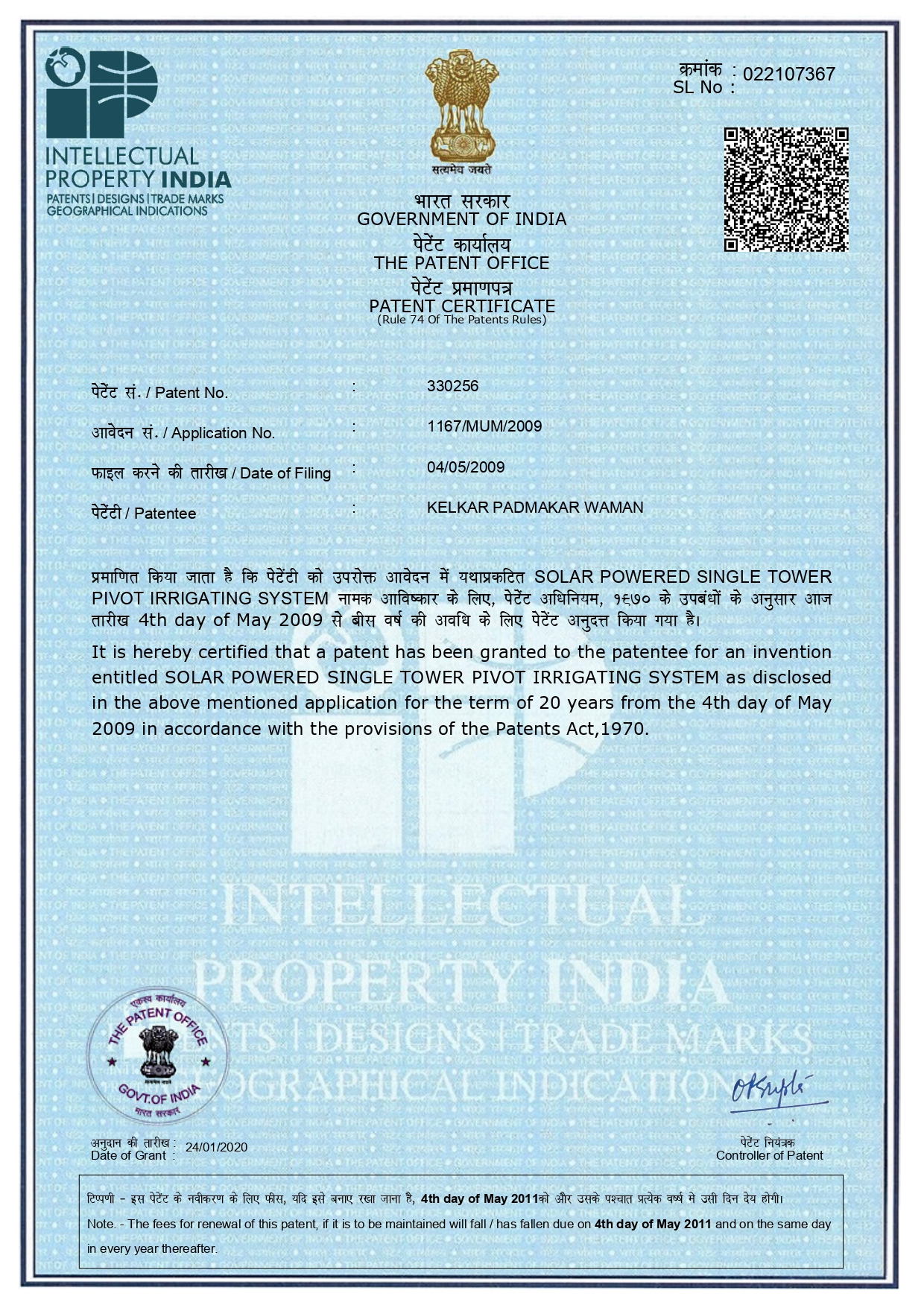

Patent Awarded

Seen form left, Bill Reuyer (From U.S.A), Padmakar Kelkar Bright Stars Electronics, Pune and The Happy Farmers....

Single-Tower System Tentative Pricing

| Towers | 1 |

| Size Mtrs | 60 |

| Acerages with End Gun Ha. | 1.45 |

| Basic Price | 450000 |

| End Gun with Pump | 75000 |

| Solar System | 75000 |

| Pumping +Piping | 100000 |

| Installation & comssioning | 50000 |

| Trials & Testing | 50000 |

| Towing System | 50000 |

| Sub Total | 850000 |

| Maintenance 1 st year | 25500 |

| Maintenance 2 nd year | 25500 |

| Maintenance 3rd year | 42500 |

| Total | 993500 |

Multi-Tower System Tentative Pricing

| Towers | 3 | 4 | 5 | 6 | 7 | 8 |

| Size Mtrs | 128 | 164 | 200 | 236 | 272 | 308 |

| Acerages with End Gun Ha. | 6.55 | 10.75 | 16 | 22.3 | 29.6 | 37.9 |

| Basic Price | 2000000 | 2400000 | 2800000 | 3200000 | 3600000 | 4000000 |

| End Gun with Pump | 75000 | 75000 | 75000 | 100000 | 100000 | 100000 |

| Solar System | 100000 | 100000 | 100000 | 150000 | 150000 | 150000 |

| Pumping +Piping | 250000 | 250000 | 250000 | 300000 | 300000 | 300000 |

| Installation & comssioning | 500000 | 500000 | 500000 | 600000 | 600000 | 600000 |

| Trials & Testing | 250000 | 250000 | 250000 | 250000 | 250000 | 250000 |

| Sub Total | 3175000 | 3575000 | 3975000 | 4600000 | 5000000 | 5400000 |

| Maintenance 1 st year | 95250 | 107250 | 119250 | 138000 | 150000 | 162000 |

| Maintenance 2 nd year | 95250 | 107250 | 119250 | 138000 | 150000 | 162000 |

| Maintenance 3rd year | 158750 | 178750 | 198750 | 230000 | 250000 | 270000 |

| Total | 3524250 | 3968250 | 4412250 | 5106000 | 5550000 | 5994000 |